Your Coding Challenges, Solved by Industry Experts

In fast-paced industries like food packaging, pharmaceuticals, and electronics, inconsistent product coding leads to delays, compliance risks, and wasted resources. Whether it’s unreadable batch numbers on irregular surfaces or high operational costs from frequent ink replacements, these pain points demand a professional industrial coding solution.

As leaders in coding technology, we’ve helped over 500 manufacturers optimize their workflows. Here’s a data-driven guide to selecting the best automatic batch coding machine for your needs.

Detailed Comparison: Find Your Ideal Coding Machine

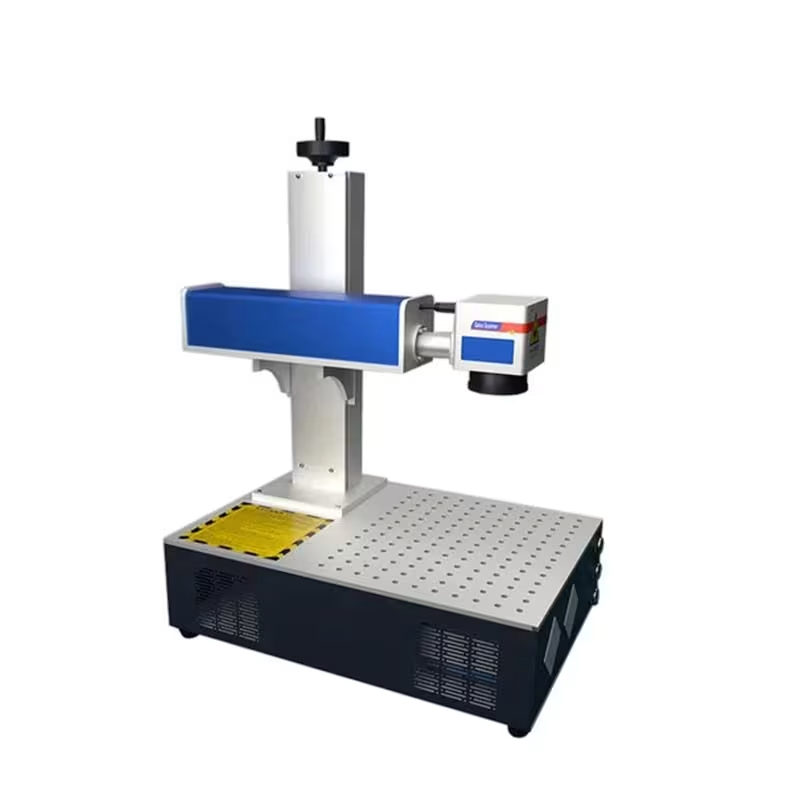

1. Laser Coding Machine vs. Inkjet Printers: Which Fits Your Line?

Technology & Speed

Zero consumables: Uses CO2, UV, or fiber lasers to etch codes permanently.

Material versatility: Works on metals, plastics, glass (avoid flammable/transparent materials).

Speed: Medium-fast, ideal for semi-automated lines.

High-speed coding: Prints 1,000+ characters/second—perfect for beverage or pharmaceutical lines.

Limitations: Requires ink; struggles with transparent surfaces.

Mid-speed: Best for food labels or cosmetics with flat surfaces.

Multi-head options: Single to quadruple heads for variable code widths.

Portability: Manual coding for small batches or irregular products (e.g., cables, pipes).

2. Material Compatibility: Avoid Costly Mistakes

What Surfaces Can You Code?

| Machine Type | Suitable Materials | Avoid |

|---|---|---|

| Laser Coding Machine | Metal, wood, ceramics | Transparent/flammable |

| CIJ Printer | Paper, corrugated boxes | Glossy plastics |

| TIJ Printer | Labels, cartons | Curved/rough surfaces |

| Handheld Printer | Textiles, leather | Glass, shiny metals |

3. Cost Analysis: Balance Budget & Efficiency

Upfront vs. Long-Term Costs

- Laser Coding Machine: High initial cost (10k−10k−50k) but zero ink expenses.

- Continuous Inkjet Printer: Affordable hardware (5k−5k−15k) but annual ink costs up to $3k.

- Handheld Inkjet Printer: Lowest investment (500−500−2k) but limited to small-scale use.

-

4. Automatic Batch Coding: Stay Compliant, Stay Competitive

All machines support variable data coding, including:

- Dynamic QR codes for traceability.

- Expiry dates, lot numbers, and multilingual labels.

- Barcodes compatible with ERP systems

-

5. Future-Proof Your Line: Why Expertise Matters

A flawed coding system risks recalls or FDA non-compliance. Our engineers provide:

- Free audits to match machines with your production speed and materials.

- 24/7 support for laser coding machines, CIJ printers, and other industrial coding solutions.

-

Ready to Upgrade? Get Your Free Consultation Today!

Don’t let coding errors slow you down. Contact us for a tailored automatic batch coding machine that guarantees precision, compliance, and ROI. As ISO-certified experts, we deliver high-performance, cost-effective solutions—because your success is our code.