Categorys

Hot Product

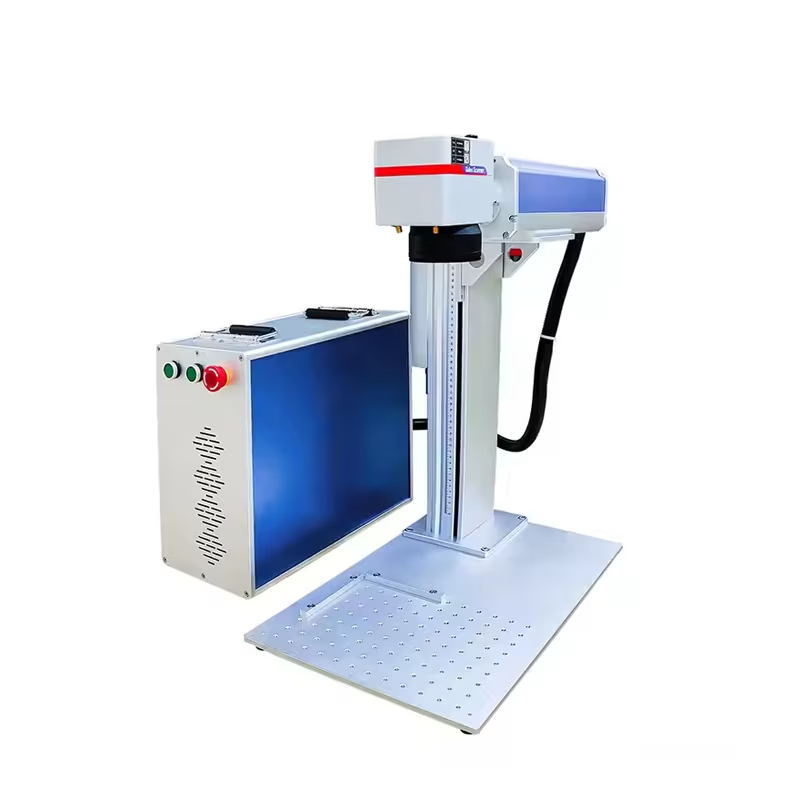

Laser Fiber Marking Machine PA-F100

Laser Fiber Marking Machine PA-F110

Laser Fiber Marking Machine HS Code:8456100090

Laser Fiber Marking Machine PA-F110 Laser Power:20/30/50/80/100W

Marking Range:110×110, 150×150, 300×300 mm

Print Speed:≤7000MM/S

Language:25+ Languages Supported

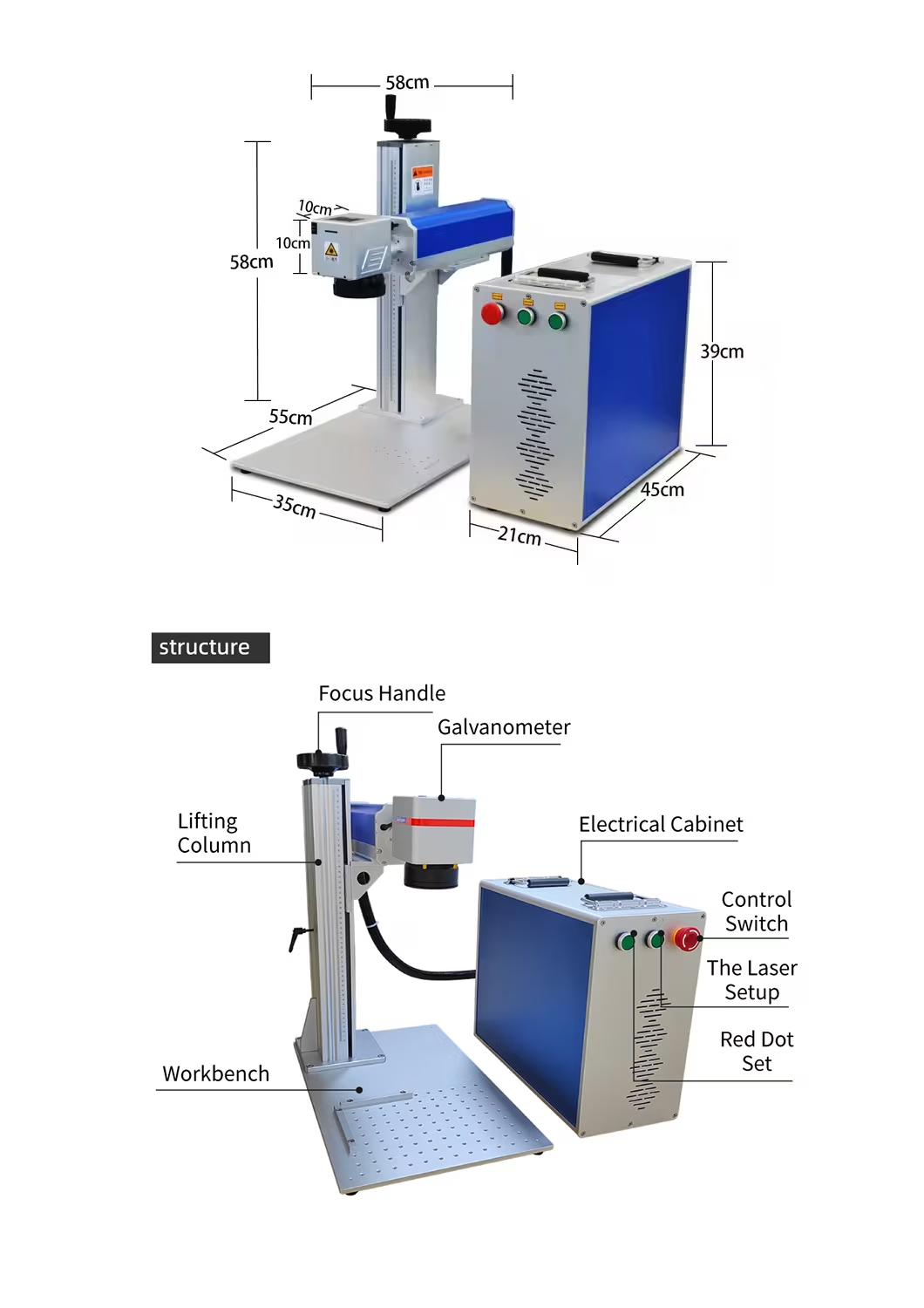

Dimensions:460*350*600mm

Laser Fiber Marking Machine PA-F110

Laser Fiber Marking Machine PA-F100 | High-Speed Precision Marking

High-Speed, High-Precision, and Versatile Marking for Every Industry

The PA-F100 Laser Fiber Marking Machine combines speed, precision, and flexibility in one compact design. Ideal for electronics, automotive, medical devices, and more, it marks metals, plastics, and ceramics with unmatched accuracy.

Core Advantages of Laser Fiber Marking Machine

- Speed: Up to 7000mm/s – industry-leading for faster production.

- Precision: Detail-oriented with ±0.002mm accuracy and 0.012mm line width.

- Versatility: Marks metal, plastic, and ceramic materials, perfect for diverse applications.

- Durability: Over 100,000 hours of service life, ensuring long-term reliability.

- User-Friendly: Intuitive interface and multi-language support make it easy to operate.

- Compact & Lightweight: Fits into tight spaces – 550mm x 550mm x 650mm, weighing just 32kg.

Why Choose Our Laser Fiber Marking Machine?

- No Consumables: No ink or labels needed – just pure laser efficiency.

- Eco-Friendly: Low power consumption (500W max) reduces costs and environmental impact.

- Flexible Marking: Perfect for text, QR codes, barcodes, and logos.

- Built for the Long Haul: Air cooling system ensures stable performance around the clock.

Wide Application of Laser Fiber Marking Machine

- Electronics: Circuit boards, connectors, components.

- Automotive: Engine parts, control panels, labels.

- Medical: Surgical tools, implants, and more.

For more information or a demo, reach out today and discover how the PA-F100 Laser Fiber Marking Machine can streamline your production.

| Parameter | Specification |

|---|---|

| Laser Power | 20W/30W/50W/80W/100W (Selectable) |

| Wavelength | 1064nm (Fiber Laser Standard) |

| Beam Quality | <2 (M² Factor) |

| Operation Mode | Pulsed/Continuous Switchable |

| Service Life | >100,000 Hours (24/7 Operation) |

| Cooling System | Air Cooling CE Certified |

| Power Supply |

|

| Environmental Tolerance |

|

| Physical Dimensions | 550×550×650mm (W×D×H) |

| System Weight | <32kg (Excluding Accessories) |

| Engraving Depth | ≤0.5mm (Material Dependent) |

| Maximum Speed | ≤7000mm/s (Industry Leading) |

| Working Area |

|

| Minimum Feature Size |

|

| Positioning Accuracy | ±0.002mm ISO 9013 |

| Supported Content |

|

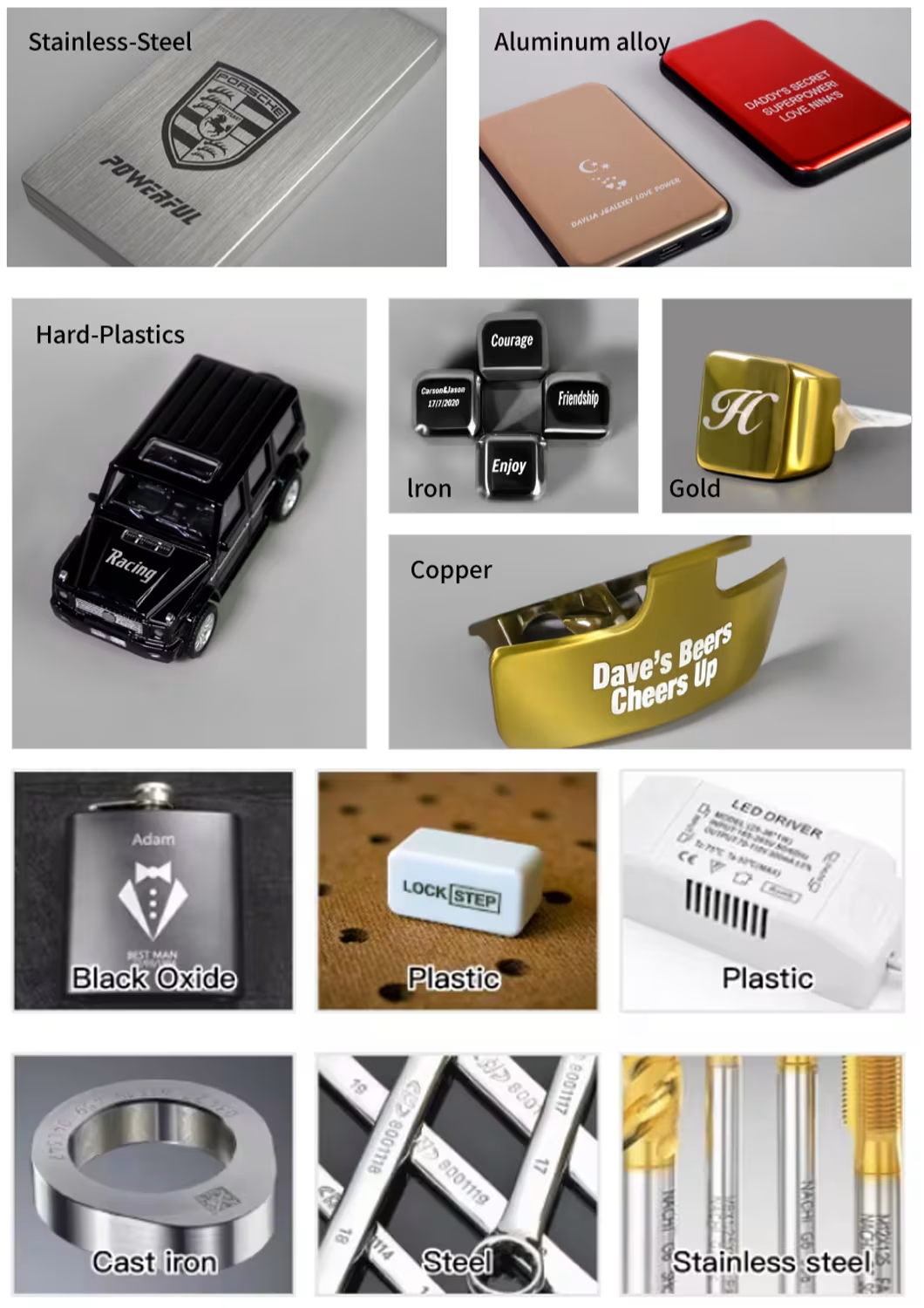

Laser Fiber Marking Machine - Compatible Materials Overview

Metal Materials (95%+ Compatibility)

- Industrial Metals: Stainless Steel | Carbon Steel | Titanium | Tungsten

- Non-Ferrous Alloys: Aluminum 6061 | Aerospace-grade Aluminum | Brass | Copper

- Precious Metals: Gold (24K/18K) | Silver (.925 Sterling) | Platinum

- Specialized Compounds: Cemented Carbide | Nickel Alloys | Carbide Tools

- Note: Optimal results achieved on clean surfaces with 0.1-3mm material thickness

Laser Fiber Marking Machine for Plastic/Non-Metal Materials

- ABS | PE (Polyethylene) | PVC | Nylon

- Polycarbonate | Acrylic (PMMA)

Surface Treatments with Laser Fiber Marking Machine

- Anodized Aluminum Removal | Powder Coating Stripping

- Ceramic Scribing (0.2mm precision)

- Material testing recommended due to formulation variances

Technical Specifications of Laser Fiber Marking Machine

- Marking Depth: 0.01-0.5mm (adjustable)

- Surface Prep: Degreasing required for oily materials

- Color Contrast: Natural oxidation effect on most metals