Smart Sensitive 5-inch touch screen

Smart 5-inch touch screen for easy operation. One-touch control simplifies inkjet printing and adjustments.

High-Speed Printing:

Thermal Inkjet Printer PA-T501 achieves impressive printing speeds of up to 60 meters per minute. It is ideal for high-volume production environments where fast and reliable coding is essential. With this printer, businesses can maintain consistent productivity without compromising on print quality.

Flexible and Precise Printing:

Equipped with a TIJ 2.5 thermal foam nozzle, the PA-T501 delivers exceptional print resolution up to 600 DPI. It offers flexible printing heights ranging from 1.2mm to 50mm, allowing it to accommodate various material sizes. Whether printing barcodes, dates, or logos, it ensures clear and sharp output.

Efficient and User-Friendly Interface:

Thermal Inkjet Printer PA-T501 is designed for ease of use. Its 7-inch capacitive touchscreen enables intuitive operation with minimal training. The printer supports multiple ink types, including quick-dry solvent and water-based inks, and offers adjustable printing lines for versatile applications.

In-depth display of the key technologies, unique features, and excellent design of the thermal inkjet coding machine so that you can fully understand its advantages and performance.

Smart 5-inch touch screen for easy operation. One-touch control simplifies inkjet printing and adjustments.

Ensures precise inkjet coding for medium/low-speed lines. Stable operation all day, enhancing production efficiency.

Fast and precise sensing sensor for accurate detection, ensuring quick and reliable inkjet coding.

Separate design with an adjustable bracket for easy assembly. Compact size and versatile, making it suitable for a wide range of applications.

New nozzle with high strength and corrosion resistance, available in two sizes: 12.7mm and 25mm, ensuring durability and reliable performance.

Fast-drying and durable 42ml ink cartridge, designed for consistent performance and efficient, long-lasting inkjet printing.

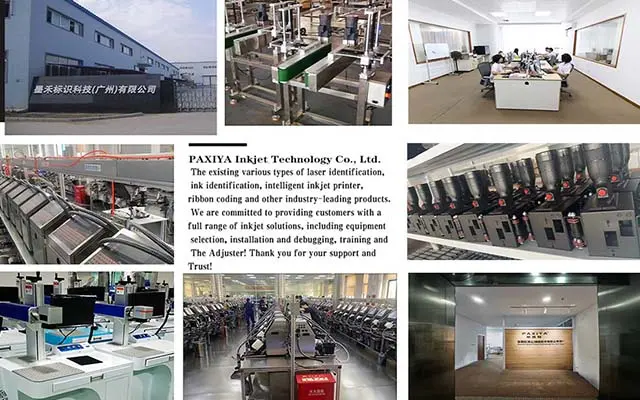

High-quality products, good service, competitive price. Meanwhile, ODM and OEM orders are available.

Independent product research team. Provide customers with the most advanced coding technology services.

One-year warranty and lifetime maintenance for all coding machines and inkjet printers.

Our high-quality inkjet printer and laser marking machines have been sold all around the world.

Focus on coding marking equipment, research and development production and sales for more than 10 years.

We have more than 10 product patent certificates (e.g., CE, FCC, appearance patents).

| Parameter | Specification |

|---|---|

| Product Name | Online Intelligent Inkjet Printer |

| Machine Size | Large: 650x150x500mm, Small: 550x100x200mm |

| Inkjet Lines | 1 - 6 lines adjustable |

| Inkjet Height | 12.4/25.4mm |

| System Language | Built - in 38 languages |

| Printing Distance | 1 - 10mm mechanical adjustment (The optimal distance between the nozzle and the printing object is 2 - 5mm) |

| Inkjet Content | Text, barcodes, dates, graphic logos, QR codes, etc. |

| Inkjet Materials | Cartons, metals, plastics, wood, stone, electronics, glass |

| Screen Size | 5 inches |

| Storage Information | USB flash drive and local machine |

| Inkjet Precision | 300-600DPI |

| External Interface | Photoelectric interface, USB interface |

| Printing Direction | 360 - degree adjustable |

Whether it is competitive or effective, our automatic coding machine equipment can provide a high-quality use experience suitable for various industry

Floor bracket is movable and adjustable, allowing installation without drilling holes in the production line. The coding position can be easily changed as needed.

Fully automatic paging transport system for paper, It efficiently handles the task of manual code placement, reducing workload and improving productivity.

Movable floor bracket can be easily adjusted without the need for drilling holes in the production line, allowing flexible positioning of the coding machine.

Initial communication with customers to understand project needs and ensure accurate customization

The expert team analyzes feasibility based on customer needs and market standards for quality.

Design team creates models and renderings based on customer needs, moving to production after approval.

Verify product functions, technical parameters, and materials to meet customer application needs.

Product samples are made based on the confirmed design for customer testing to meet standards.

Once confirmed, large-scale production begins based on customer order and delivery schedule.

After production, products are inspected, approved, and professionally packaged for safe transport.

Deliver on time, provide installation guidance or on-site support for smooth operation