The can industry

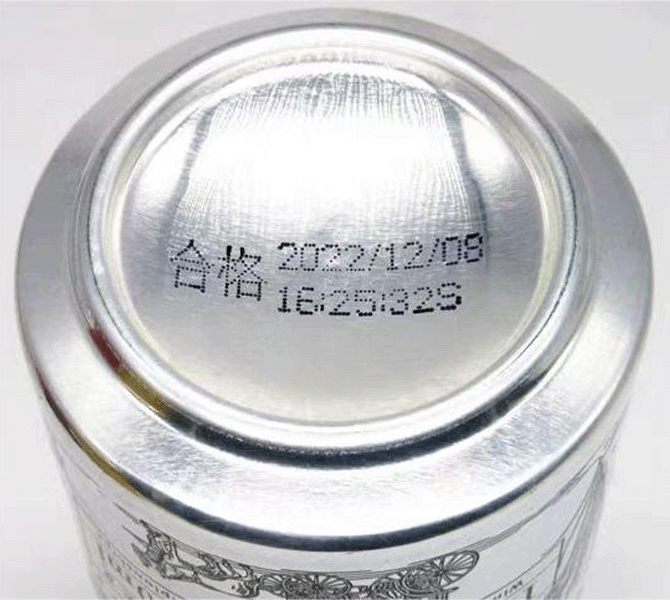

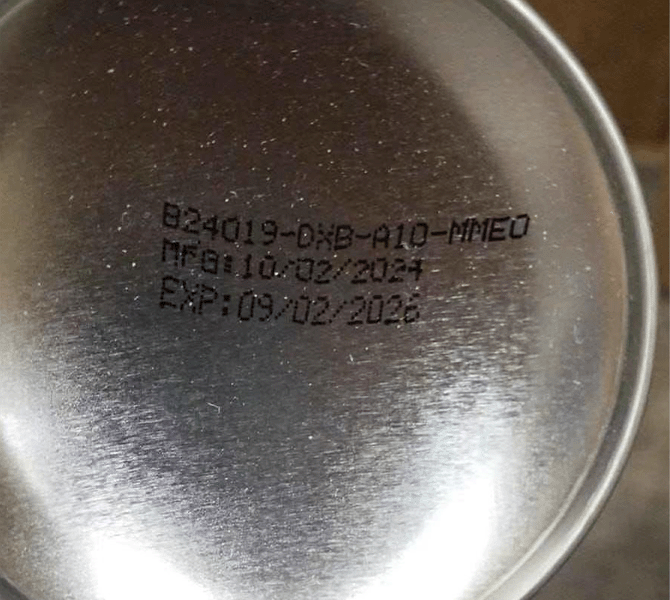

The laser equipment of the inkjet printer can spray print on the can, such as the production date, batch number, etc., to achieve product traceability and management

Product Information Communication

The identification provides product information, such as content, ingredients, nutritional information, production date, shelf life, etc., to help consumers make purchasing decisions

Quality assurance

Through identification, the production batch and inspection qualification information of the product can be tracked, which is crucial for ensuring the consistency and reliability of the product.

Anti counterfeiting and brand protection

The can industry also faces the risk of counterfeit and inferior products. The use of special identification techniques, such as holographic identification and tamper proof labels, can help prevent forgery and infringement, and protect brand reputation

The application of inkjet printers in the can industry is mainly reflected in the following aspects

Production date printing

- It has become a common practice in the industry for inkjet printers to print production dates on cans. This printing method requires the inkjet printer to be linked with the can production line to ensure the clarity and adhesion of the printing, in order to prevent it from being rubbed off during transportation.

- The inkjet printer can adapt to production lines of different speeds, including low-speed and high-speed production lines, to meet various production needs.

Personalized customization

- With the increasing demand for personalization among consumers, inkjet printers are also being used for personalized customization on cans. For example, printing specific patterns, text, or QR codes to enhance the uniqueness and appeal of the product.

High quality graphic printing

- By using UV inkjet printing technology, high-quality graphics can be printed directly on the surface of cans. This technology can print patterns with bright colors and rich details, providing a unique visual effect for cans.

- UV inkjet printing has received attention in the direct molding printing market and is gradually being applied in the can industry.

Production efficiency and cost optimization

- The application of inkjet printers in the can industry has improved production efficiency. Compared to traditional printing methods, inkjet printing can complete printing tasks faster and reduce production time.

- Meanwhile, inkjet printing can also reduce production costs. For small batch production or personalized customization needs, inkjet printing does not require expensive printing plates, reducing initial investment costs.

Environmental Protection and Sustainability

- The ink used in inkjet printers is mostly water-based or environmentally friendly, which is more environmentally friendly than the ink used in traditional printing.

- In the process of recycling and reusing cans, inkjet printed ink is easier to clean and process, which meets the requirements of environmental protection and sustainable development.

The application of inkjet printers in the can industry covers production date printing, personalized customization, high-quality graphic printing, production efficiency and cost optimization, as well as environmental protection and sustainability. With the continuous progress of technology and changes in market demand, the application of inkjet printers in the can industry will be more extensive and in-depth.

Show results

Service Process Steps

Requirement Confirmation

Communicate with customers to understand their needs and requirements, including identifying equipment specifications, functions, quantities, etc.

Requirement Confirmation

Design And Development

Design and develop equipment based on customer needs. This may involve work in hardware design, software programming, and other aspects.

Design And Development

Sample Production

Based on the design and development results, produce sample equipment that meets customer requirements. Customers can test and evaluate samples to determine if their needs are met.

Sample Production

Mass Production

Once the sample equipment is approved by the customer, mass production can begin. According to the order quantity, manufacture equipment and implement strict quality control.

Mass Production

Installation And Debugging

Install the produced equipment in the location specified by the customer, and conduct debugging and testing to ensure the normal operation of the equipment.

Installation And Debugging

After Sales Service

Provide customers with after-sales service, including equipment repair, maintenance, training, etc. Ensure the smooth operation of the equipment during use.