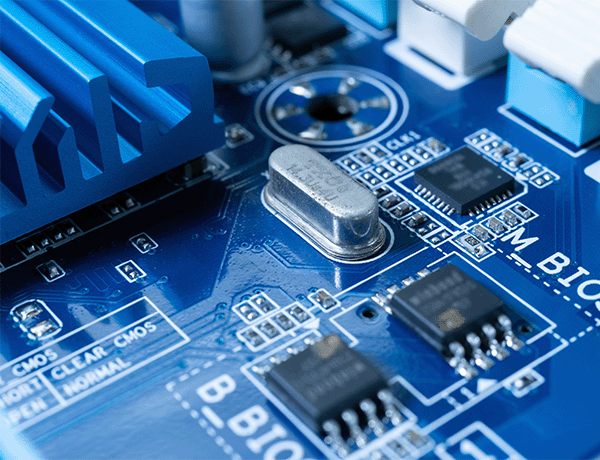

Electronics industry

Laser equipment for inkjet printers can be used for electronic product identification and traceability, such as serial numbers, barcodes, and QR codes on products such as mobile phones and computers.

Product Tracking and Quality Managemen

Labels can help manufacturers track the production, testing, distribution and after-sales service of products. Through labels, product batches, production dates, manufacturers and other information can be quickly identified, which is convenient for quality control and problem tracing.

Regulatory Compliance and Safety Certification

Electronic products need to comply with various international and regional regulatory standards, such as CE marking, FCC certification, etc. Labels ensure that products comply with these regulatory requirements and are clearly marked on the products.

Brand Protection and Anti-Counterfeiting

Labels help protect brands from counterfeit and shoddy products. By using special labeling technologies such as holographic labels, tamper-proof labels, etc., products can be effectively prevented from being counterfeited.

User Guidance and Safety Warnings

Electronic products usually require users to provide operating instructions and safety warnings. Labels provide information on how to use the product safely, including power requirements, operating procedures, maintenance and cleaning methods, etc.

Inkjet Printing Technology

The ink droplets produced by inkjet printing technology will be present in the fluid channel with a diameter ranging from 10 to 150 μm, 6 approximately equal to the nozzle diameter. The volume of the droplets is in the picoliter range. This technology is considered suitable for the field of printed electronics due to the following reasons:

- It is a non-contact process that selectively deposits a variety of materials onto a variety of substrates in a drop-by-drop manner.

- Shop floor space requirements, initial investment, and time to get an inkjet printing unit up and running are lower than most other printing technologies.

- It is suitable for various production scales from prototypes to large-scale industrial production.

- Ink consumption and material waste are minimal.

- Its positioning in the process chain is very flexible.

Inkjet printing technology can be used to add functionality to substrates that already have electronic structures and devices fabricated using other technologies. Its non-contact, mask-less and master-less nature, as well as the freedom to position the print head directly on top of any 3D coordinate on the substrate, makes this functionality possible.

Show results

Service Process Steps

Requirement Confirmation

Communicate with customers to understand their needs and requirements, including identifying equipment specifications, functions, quantities, etc.

Requirement Confirmation

Design And Development

Design and develop equipment based on customer needs. This may involve work in hardware design, software programming, and other aspects.

Design And Development

Sample Production

Based on the design and development results, produce sample equipment that meets customer requirements. Customers can test and evaluate samples to determine if their needs are met.

Sample Production

Mass Production

Once the sample equipment is approved by the customer, mass production can begin. According to the order quantity, manufacture equipment and implement strict quality control.

Mass Production

Installation And Debugging

Install the produced equipment in the location specified by the customer, and conduct debugging and testing to ensure the normal operation of the equipment.

Installation And Debugging

After Sales Service

Provide customers with after-sales service, including equipment repair, maintenance, training, etc. Ensure the smooth operation of the equipment during use.