Food packaging industry

The application of inkjet printers in the food industry not only improves production efficiency and reduces costs, but also provides consumers with more diverse and personalized food choices. With the continuous development of technology, the application of inkjet printers in the food industry will be more extensive and in-depth.

Product traceability and safety management

Tracking the source, production date, shelf life, and other information of the product through identification is crucial for food safety. Once food safety issues arise, they can be quickly traced back to specific batches and corresponding measures can be taken to ensure the health of consumers.

Compliance with regulations and standards

The food industry is subject to strict regulations and standards. Identification helps manufacturers comply with these regulations, such as food labeling regulations, nutritional labeling requirements, etc., to ensure that products are sold legally in the market.

Consumer information provision

Identification provides consumers with important information about the product, such as ingredients, nutritional value, allergen information, etc., helping them make informed purchasing decisions.

Anti counterfeiting and brand protection

High quality identification can prevent forgery and infringement, protect brand intellectual property rights and consumer interests.

The application of inkjet printers in the food industry is becoming increasingly widespread, mainly reflected in the following aspects

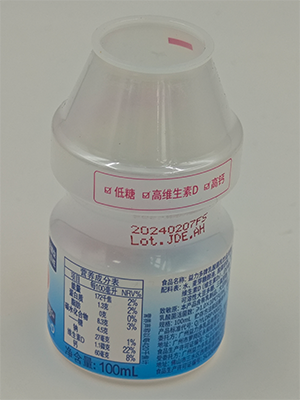

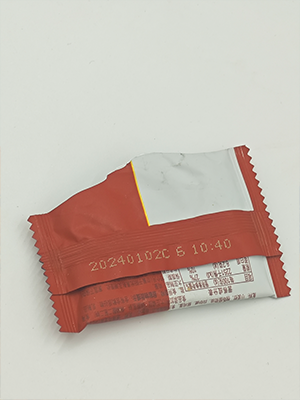

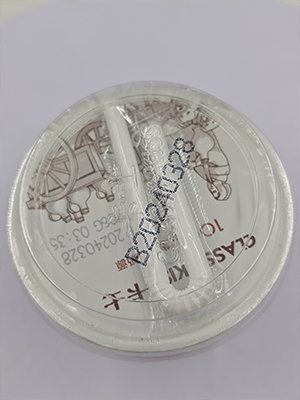

Food safety traceability and date marking

- Inkjet printers can print real-time production date, expiration date, batch number, barcode, QR code and other information on food packaging, which is crucial for food tracking and quality management. These traceability information facilitate consumers to understand the production information of products, and can also help enterprises track the production, circulation, and sales process of products, ensuring food safety.

Edible ink

- In the application of inkjet printers in the food industry, edible ink is used. This ink is made from natural pigments and all ingredients are edible. It can be directly or indirectly used on the surface of food.

- These inks are not only safe and healthy, but also have beautiful colors, which can enhance the artistic and added value of the product.

Food packaging printing

- In the food packaging industry, inkjet printers also play an important role. Inkjet printers can perform high-speed and continuous inkjet printing on packaging boxes and bags of various materials, such as production date, expiration date, barcode, QR code, and other information.

- Inkjet printers is widely used in packaging food, such as food packaging boxes, packaging bags, and bottled food. By installing photoelectric sensors and nozzle brackets, fast moving food on the production line can be stably assigned positioning codes and coding codes.

Brand protection and anti-counterfeiting

- By using inkjet printers to print unique logos, serial numbers, or QR codes on product packaging, food manufacturers can enhance brand protection and prevent the circulation of counterfeit and inferior products. These labels can also be used by consumers to verify the authenticity of products

The application of inkjet printers in the food industry not only improves production efficiency and reduces costs, but also provides consumers with more diverse and personalized food choices. With the continuous development of technology, the application of inkjet printers in the food industry will be more extensive and in-depth.

Show results

Service Process Steps

Requirement Confirmation

Communicate with customers to understand their needs and requirements, including identifying equipment specifications, functions, quantities, etc.

Requirement Confirmation

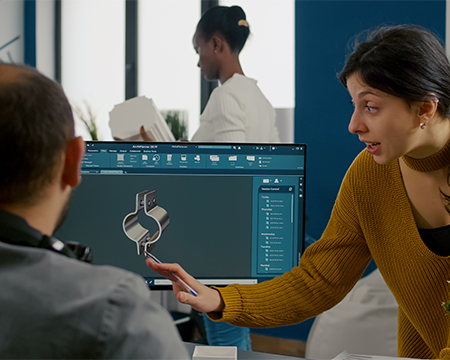

Design And Development

Design and develop equipment based on customer needs. This may involve work in hardware design, software programming, and other aspects.

Design And Development

Sample Production

Based on the design and development results, produce sample equipment that meets customer requirements. Customers can test and evaluate samples to determine if their needs are met.

Sample Production

Mass Production

Once the sample equipment is approved by the customer, mass production can begin. According to the order quantity, manufacture equipment and implement strict quality control.

Mass Production

Installation And Debugging

Install the produced equipment in the location specified by the customer, and conduct debugging and testing to ensure the normal operation of the equipment.

Installation And Debugging

After Sales Service

Provide customers with after-sales service, including equipment repair, maintenance, training, etc. Ensure the smooth operation of the equipment during use.