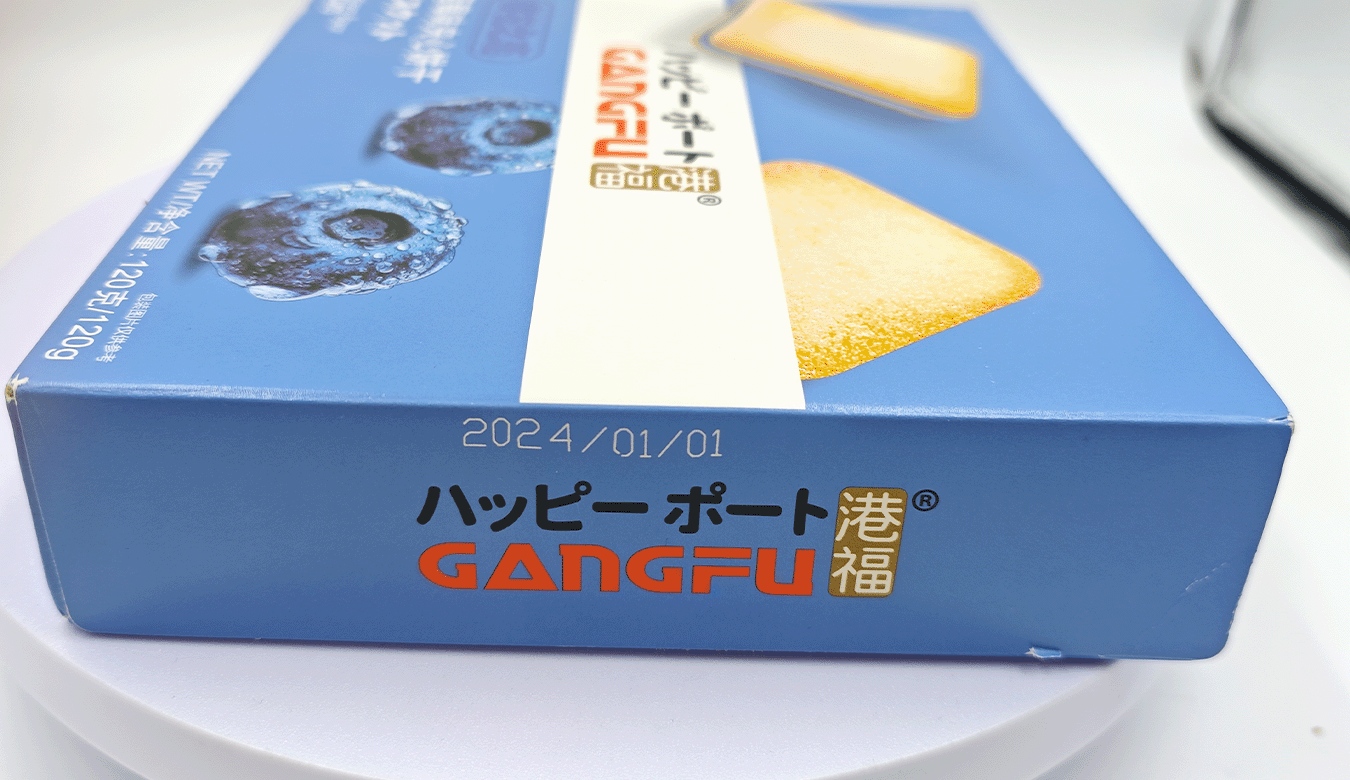

Paper box packaging industry

Identification equipment can be used for inkjet printing on paper box packaging, such as production date, product information, etc., to achieve packaging identification and traceability.

Efficient information labeling

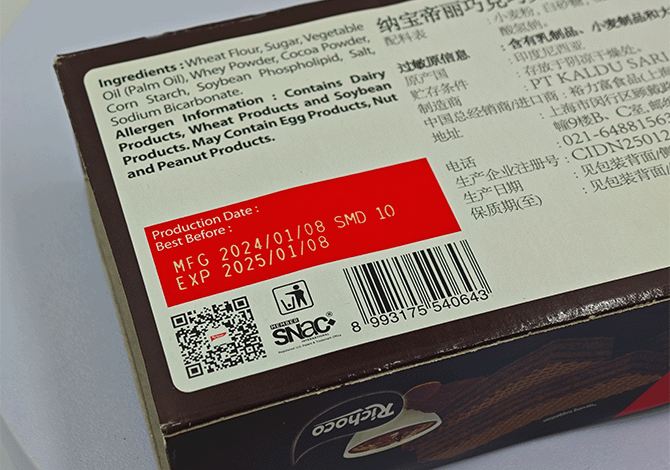

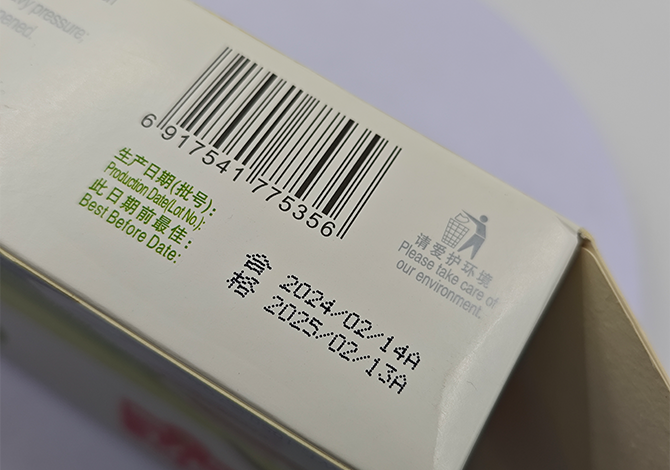

The inkjet printer can quickly and efficiently label various information on paper box packaging, such as production date, expiration date, batch number, product code, etc., improving production efficiency.

Improving product traceability

The unique identification code printed by the inkjet printer can effectively track the entire process of product production and distribution, which helps with quality control and management.

Flexibility

The inkjet printer can easily adjust the printing content, suitable for diverse packaging needs and frequent replacement of product information.

Reducing human errors

The automated inkjet process reduces the possibility of manual errors and improves the accuracy and consistency of information

The application of inkjet printers in the paper box packaging industry is mainly reflected in the following aspects

Personalized customization

- Inkjet printers can achieve fast and low-cost personalized printing, meeting the market's demand for customized packaging. For example, specific patterns, text, or barcode QR codes can be printed on paper boxes according to customer requirements.

Flexibility and Variable Data Printing

- Inkjet printers support variable data printing and can print different information such as batch number, production date, serial number, etc. on each paper box, which is very useful for product tracking and inventory management.

Environmental Protection and Sustainability

- The water-based ink used in inkjet printers has a relatively small impact on the environment and meets the current market requirements for environmental protection and sustainability.

Strong adaptability

Inkjet printers can adapt to various types of paper and paper box materials, with good material compatibility.

Durability

- The ink printed on paper boxes by inkjet usually has good water resistance and scratch resistance, and can maintain a long time of non fading even during transportation and storage.

Flexibility

- Inkjet printers can easily achieve variable data printing, such as batch number, serial number, production date, etc., which is very useful for product tracking and personalized customization

Wide application range

- Inkjet printers can be used for various applications of paper box packaging, including daily necessities, food, electronic products, etc., to meet the needs of different industries

Low cost and high cost-effectiveness

- The operating cost of inkjet printing is relatively low, eliminating intermediate consumables such as heat transfer paper, high-temperature adhesive tape, and heat transfer equipment, thereby reducing production costs.

- Inkjet printers are suitable for manufacturers and entrepreneurs in various industries, saving costs for customers and improving overall economic benefits.

Technical features and advantages

- The inkjet printer adopts non-contact printing, which can be replicated on various printing materials without being limited by paper length, and is suitable for packaging various sizes of paper boxes.

- The configuration format is flexible and can adapt to different levels of customer needs from high-end to low-end, meeting the production needs of different paper box packaging.

In summary, the application of inkjet printers in the paper box packaging industry has brought significant technological progress and economic benefits to the industry due to its convenient operation, digitization, low cost, and wide range of application areas.

Show results

Service Process Steps

Requirement Confirmation

Communicate with customers to understand their needs and requirements, including identifying equipment specifications, functions, quantities, etc.

Requirement Confirmation

Design And Development

Design and develop equipment based on customer needs. This may involve work in hardware design, software programming, and other aspects.

Design And Development

Sample Production

Based on the design and development results, produce sample equipment that meets customer requirements. Customers can test and evaluate samples to determine if their needs are met.

Sample Production

Mass Production

Once the sample equipment is approved by the customer, mass production can begin. According to the order quantity, manufacture equipment and implement strict quality control.

Mass Production

Installation And Debugging

Install the produced equipment in the location specified by the customer, and conduct debugging and testing to ensure the normal operation of the equipment.

Installation And Debugging

After Sales Service

Provide customers with after-sales service, including equipment repair, maintenance, training, etc. Ensure the smooth operation of the equipment during use.