Pharmaceutical industry

The inkjet printer has a wide range of applications in the pharmaceutical industry, from innovation in drug supply systems to printing of medical images, to the production of medical related labels and packaging, all of which demonstrate its importance and value in the pharmaceutical field. With the continuous progress and innovation of technology, the application of inkjet printers in the pharmaceutical industry will be more extensive and in-depth.

Product tracking and traceability

The identification of drugs and other medical products helps to track the source, production batch, distribution channel, etc. of products, which is crucial for quality control and recall management

Anti counterfeiting and security

Pharmaceutical products are a high-risk area for counterfeiting and inferior quality. The use of special identification techniques, such as anti-counterfeiting labels, serialized identification, etc., can help prevent forgery and illegal distribution.

Environment and special storage conditions

Pharmaceutical products may require specific storage conditions, such as temperature control. The identification provides necessary storage and transportation guidelines to ensure the effectiveness of the product in a suitable environment.

The application of inkjet printers in the pharmaceutical industry is mainly reflected in the following aspects

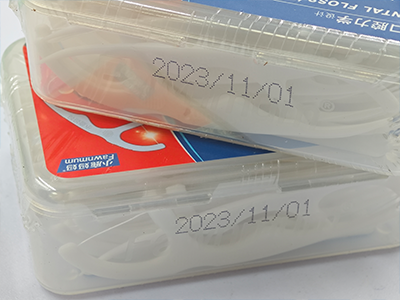

Printing of regulatory codes for drug packaging

- Inkjet printers are used on medical drug packaging to identify regulatory codes, ensuring drug traceability and compliance with regulations. These inkjet printers can provide high reading rates for barcodes while ensuring excellent readability and contrast.

Non contact inkjet printing function

- Inkjet printer adopts the latest technology of non-contact inkjet printing function, which can print on various materials of drug packaging, such as paper boxes, aluminum foil packaging, glass bottles, capsules, films, etc. This printing method is suitable for different printing needs such as forward, reverse, and reverse.

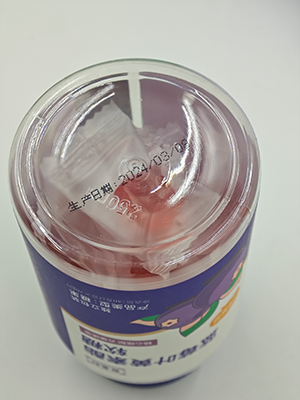

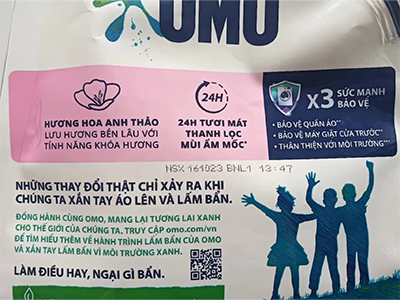

Create medical related labels and packaging

- Inkjet printers can produce various medical related labels and packaging, such as drug labels, medical device packaging, etc. These labels and packaging typically contain important medical information, such as drug name, instructions for use, expiration date, etc.

Strong adaptability, suitable for various drug packaging

- The small character inkjet printer is suitable for various drug packaging forms such as medicine boxes, medicine bottles and ampoules, labels, infusion bags, flexible materials, tubes, tin foil bubbles, aluminum-plastic bubble covers, double aluminum packaging, etc. This diversity enables inkjet printers to meet the different packaging needs of the pharmaceutical industry

Environmental protection and sustainable development

- The ink used in inkjet printers is usually environmentally friendly, which is a bonus for healthcare institutions that prioritize environmental protection. In addition, some inkjet printers also support the use of recycled ink cartridges to further reduce environmental impact.

Inkjet printers have a wide range of applications in the pharmaceutical industry, as evidenced by their importance and value in the production of medical related labels and packaging. With the continuous progress and innovation of technology, the application of inkjet printers in the pharmaceutical industry will be more extensive and in-depth.

Show results

Service Process Steps

Requirement Confirmation

Communicate with customers to understand their needs and requirements, including identifying equipment specifications, functions, quantities, etc.

Requirement Confirmation

Design And Development

Design and develop equipment based on customer needs. This may involve work in hardware design, software programming, and other aspects.

Design And Development

Sample Production

Based on the design and development results, produce sample equipment that meets customer requirements. Customers can test and evaluate samples to determine if their needs are met.

Sample Production

Mass Production

Once the sample equipment is approved by the customer, mass production can begin. According to the order quantity, manufacture equipment and implement strict quality control.

Mass Production

Installation And Debugging

Install the produced equipment in the location specified by the customer, and conduct debugging and testing to ensure the normal operation of the equipment.

Installation And Debugging

After Sales Service

Provide customers with after-sales service, including equipment repair, maintenance, training, etc. Ensure the smooth operation of the equipment during use.