Plastic industry

The application of inkjet printers in the plastic industry has advantages such as wide adaptability, high-quality printing effects, wide application areas, suitability for small batch production and personalized customization, and breaking through the limitations of traditional printing methods.

Product identification

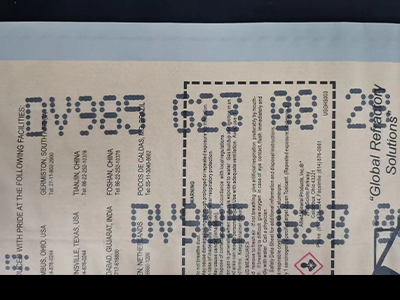

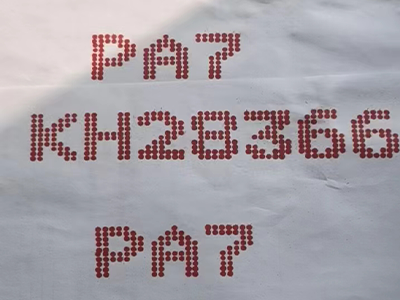

Identification helps consumers and producers identify the type, purpose, size, material, and other information of the product, which is crucial for the correct use and inventory management of the product.

Security and Compliance

Plastic products need to comply with specific safety standards and regulatory requirements, such as safety standards for food contact materials and safety regulations for children's products. Identification ensures that the product meets these requirements and communicates product compliance to users.

Quality Control

Through identification, the production batch and inspection qualification information of the product can be tracked, which is crucial for ensuring the consistency and reliability of the product

Environmental Protection

With the increasing awareness of environmental protection, the recyclability of plastic products and the use of environmentally friendly materials are also receiving increasing attention. Identification can help consumers understand the environmental attributes of products and make more sustainable choices.

The application of inkjet printers in the plastic industry is mainly reflected in the following aspects

Material compatibility

- Inkjet printers can adapt to various plastic materials, such as polyethylene (PE), polypropylene (PP), polyvinyl chloride (PVC), polyester (PET), etc. These materials are commonly used to make plastic bottles, containers, packaging films, etc. Inkjet printers can print clear and long-lasting images and text on these materials.

Printing quality

- Inkjet printers can provide high-resolution printing effects, achieving delicate printing quality even on plastic surfaces, which is crucial for product appearance and brand image.

Durability

- Ink printed on plastic by inkjet usually has good chemical and scratch resistance, and can maintain color fastness for a long time even in harsh environments.

Flexibility

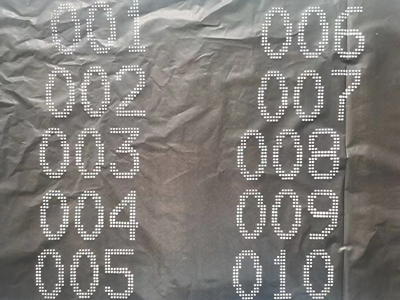

- Inkjet printers can easily achieve variable data printing, such as batch number, serial number, production date, etc., which is very useful for product tracking and personalized customization.

Cost effectiveness

- Compared to traditional printing methods, inkjet printing typically has lower setup costs and faster turnaround times, making it particularly suitable for short format printing and small batch production.

Environmental friendliness

- The ink used in inkjet printers is usually based on water or eco-friendly solvents, which helps reduce the impact on the environment.

Widely applicable

- Inkjet printers can be used for various applications of plastic products, including daily necessities, packaging, building materials, electronic products, etc., to meet the needs of different industries.

Show results

Service Process Steps

Requirement Confirmation

Communicate with customers to understand their needs and requirements, including identifying equipment specifications, functions, quantities, etc.

Requirement Confirmation

Design And Development

Design and develop equipment based on customer needs. This may involve work in hardware design, software programming, and other aspects.

Design And Development

Sample Production

Based on the design and development results, produce sample equipment that meets customer requirements. Customers can test and evaluate samples to determine if their needs are met.

Sample Production

Mass Production

Once the sample equipment is approved by the customer, mass production can begin. According to the order quantity, manufacture equipment and implement strict quality control.

Mass Production

Installation And Debugging

Install the produced equipment in the location specified by the customer, and conduct debugging and testing to ensure the normal operation of the equipment.

Installation And Debugging

After Sales Service

Provide customers with after-sales service, including equipment repair, maintenance, training, etc. Ensure the smooth operation of the equipment during use.