Steel pipe and cable industry

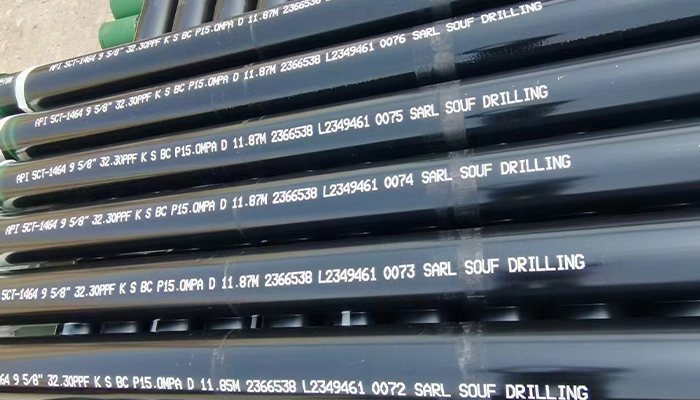

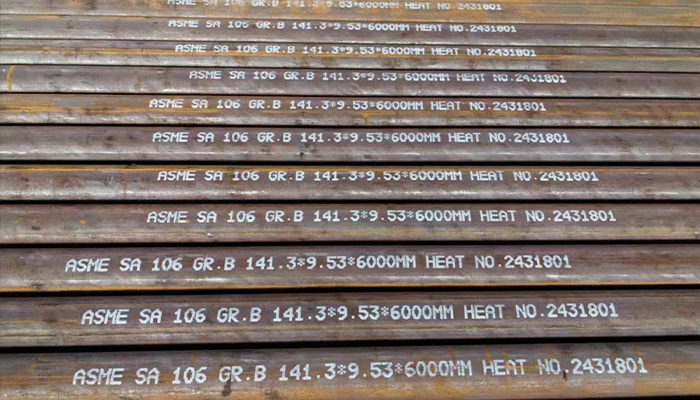

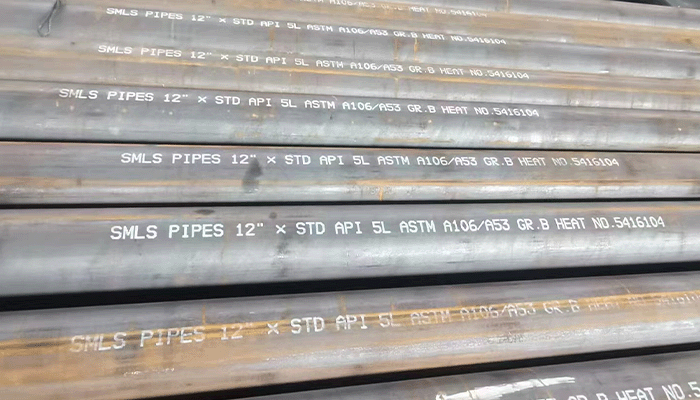

Product identification and tracking

Security and Compliance

Quality control and assurance

Anti counterfeiting and brand protection

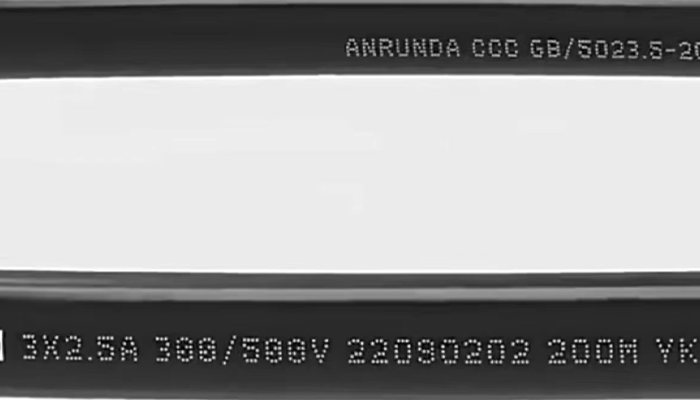

The application of inkjet printers in the steel pipe and cable industry is mainly reflected in identification and marking. The following is a detailed application analysis:

High Definition and Stability: The inkjet printer not only meets general labeling requirements, but also has stable operating quality and high-definition inkjet coding, ensuring the clarity, durability, and easy resolution of cable and wire products

Multi angle inkjet printing: The inkjet printer can achieve a 360 degree inkjet printing angle, making it easy to print in shapes such as circles, bends, and stripes, as well as at the bottom, sides, and top.

Special application requirements: The series of inkjet coding machines comply with the standards and special application requirements of the wire and cable industry. For example, special ink is used to ensure that the coding will not wear and fade during winding, and small information can be printed up to 0.8 millimeters.

Automation and connectivity: The inkjet printer can be connected to other electronic devices, such as coiling machines, cutting machines, weighing machines, etc. It can also be linked to the factory's automation management system to achieve automation and intelligence in the production process.

Show results

Service Process Steps

Requirement Confirmation

Requirement Confirmation

Design And Development

Design And Development

Sample Production

Sample Production

Mass Production

Mass Production

Installation And Debugging

Installation And Debugging