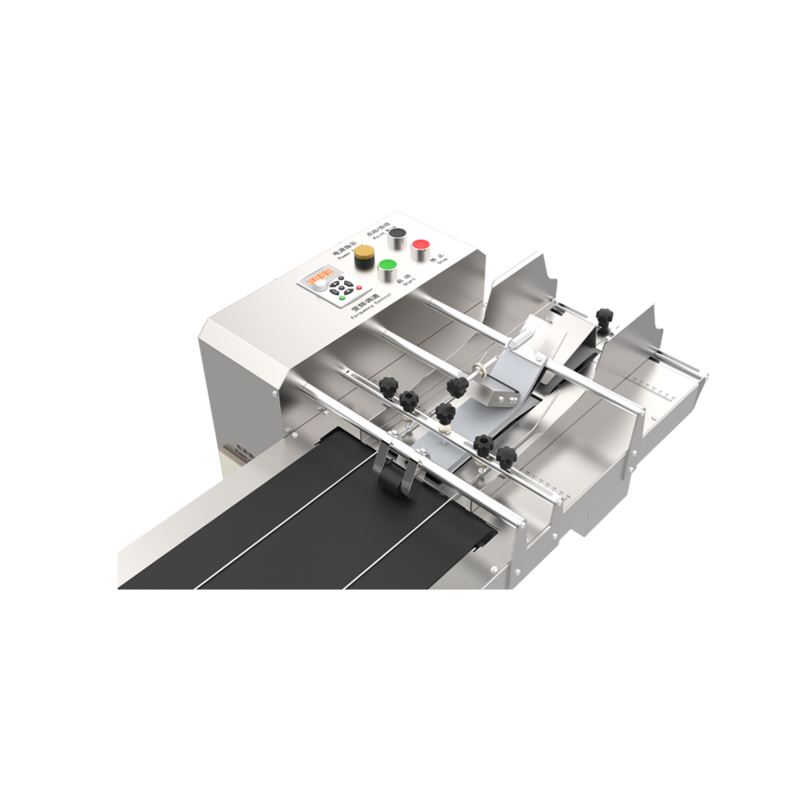

FeedersDispensers

Feeders/Dispensers feature high-speed paging and coding, multi-function operation, automatic identification and positioning, and easy operation and maintenance. They can improve work efficiency on the production line and reduce labor costs. They are one of the important equipment in the warehousing and processing industry.

Characteristic:

Efficient paging: The material paging machine adopts advanced paging technology and equipment, which can separate and organize materials with high efficiency and improve production efficiency.

Automated operation: This equipment adopts an automated control system, which can realize automatic feeding, paging, discharge and other operations, reducing manual operations and improving work efficiency.

Versatility: The material sorting machine can be applied to various types and specifications of materials, including paper, plastic sheets, metal plates, etc., and has strong adaptability.

Precise paging: This equipment can accurately separate materials, maintain the integrity of the materials, reduce the damage rate, and improve product quality.

Cost saving: By efficiently sorting and sorting materials, manual operations and labor intensity can be reduced, production costs can be reduced, and economic benefits can be improved.

Specification Parameters

| Product name | Fully automatic standard feeder/distributor |

| Product power | 120W |

| Conveying speed | 10-50 meters/minute (speed adjustable) |

| Product load | 8KG |

| Power supply voltage | AC220V/50HZ |

| Product size | 1500 * 480 * 890MM (transfer bandwidth 250MM) |

| Paging width | 50-300MM |

| Page thickness | 0.1-5MM |

| Scope of application | Plastic bags, cartons, paper bags, labels, pieces of paper, IC cards, masks, etc. |